At TrailHeads we are always thinking about the long run. Both in terms of how many miles we’re getting in this week, and in terms of our company’s future, and its environmental impact.

We are continually striving to have a lighter impact on the planet, while keeping you warm, comfy, and cozy on the run. We wanted to share the progress we have made, and our goals for the future in a number of key areas.

Product Materials:

As we design and create our products we are seeking to incorporate more and more certified recycled and natural materials into our line, while simultaneously maintaining and improving the quality & performance of our gear.

Since 2023 We have converted roughly 60% of our product line to recycled or natural materials and have plans to increase that percentage with every year going forward.

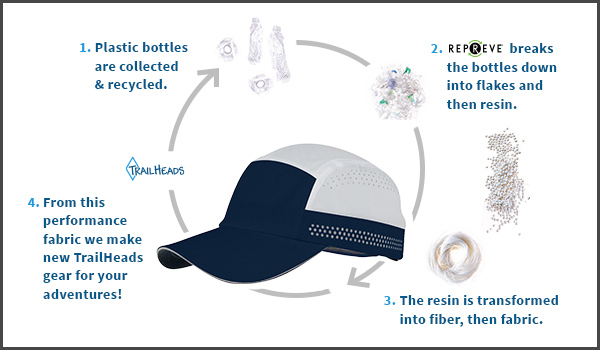

REPREVE -

One of our top partners in this quest is REPREVE. Their company uses innovative technology to transform recycled plastic bottles into performance fabrics, keeping plastic waste out of landfills. We use their recycled polyester in many of our best selling hat, headband, and glove styles, most recently we updated the fabric of our Men’s and Women’s Convertible Gloves. Check our product descriptions to see what % of recycled materials are used in your favorite styles.

Primaloft -

Primaloft are the industry experts in developing lightweight, yet incredibly warm insulation. Best of all, their insulation is made predominantly with post consumer content and recycled polyester. For our products we have chosen to use Primaloft insulations that are 90-100% recycled. You’ll find Primaloft used in our Men’s and Women’s Insulated Convertible Mittens, Quilted Trucker Hat, and Men’s and Women’s Zip Mitts.

Merino wool -

As well as recycled options, we are also seeking to work with more natural fabrics, like Merino wool. Merino is popular for a reason, it’s a renewable material that is also a high performing fabric. It’s lightweight, moisture wicking and odor resistant - perfect for runners, hikers and all kinds of athletes! Check out our growing Merino collection here.

Packaging:

Reducing the amount of plastic used in our packaging is one of our biggest challenges as a company, but we have taken a number of steps to begin mitigating its use.

We have switched to using Runhee natural hooks, which are made of reclaimed materials. When removed from the product they can be recycled once again, or they will degrade in a short period of time when sent to a landfill.

We have also switched over to using sticker hangtags on many of our styles. The hangtag has necessary barcodes & info for our retailers, but switching to the sticker reduces the shipping weight and provides you with a bonus gift to decorate your water bottle or laptop, instead of a difficult to recycle, plastic coated cardstock that’s headed quickly for the trash.

We are also working to ship more of our products from our factories in bulk instead of in individual poly bags. And we are offering more of our styles in pre-made packs and gift sets, so that customers looking for multiple colors or styles can receive them without doubling the plastic used in their shipment.

The plastic bags that we do use in shipping from the factory, we collect and take to have recycled by Trex Decking, a company that transforms recycled plastic bags into high quality, long lasting decking and outdoor furniture. You can recycle with them too! Click here to see if they collect from a dropoff in your area - it’s a great way to recycle the polymailer your hats came in!

Product Life Cycle:

The first step to improving the sustainability of a product is to make it as durable and long lasting as possible. We want to make sure our gear is with you on the trail and out of the landfill for years to come. To that end we take our time researching and sourcing materials, and we quality test rigorously before releasing a design to make sure the fabric holds up to repeated wear and washes.

On your end, to give your TrailHeads products their longest life, care for them by machine washing on a cold and delicate cycle, or hand washing them in cold water, and then let them air dry. For even greater protection, wash them in a small garment bag to keep them from catching or rubbing on rough elements of your other clothing, like zippers. These simple steps help to protect the fabric, Velcro and any reflective design elements. Using cold water also conserves energy.

When a product does ultimately reach the end of its life we recommend donating or recycling it, a practice we follow ourselves. When we receive customer returns our team evaluates their condition and then either donates them to one of our charitable partners, or recycles them with Bay State Fabric Recycling. We also donate or recycle early product samples and any unused fabric that remains after manufacturing our products. Donations go to a variety of organizations, including Footwear with Care, a local group that collects footwear and clothing for unhoused people in Hartford, CT.

Our Facilities:

Our main offices are located in Kent, CT, in a converted farmhouse, with the barn repurposed to serve as one of our warehouses.

Since taking on the property our CoFounders, Stephanie & Ed Raftery have striven to improve its eco-credentials. Both the main building and the warehouse underwent projects to reduce energy loss by adding foam insulation. We also use a heat pump for keeping the offices comfortable & energy efficient during both New England’s cold winters and its summer heat waves.

We are also excited to be in the process of going solar! Soon we hope to have an array of panels on the warehouse, providing the majority of the energy that we use in the office.